Guangdong Zhufeng Electric Co., Ltd.

GuangDong Zhufeng Electric Co.,LTD established in 2004, is a

national high-tech and energy save enterprise with approval by

National Development and Reform Commission. Focusing on the

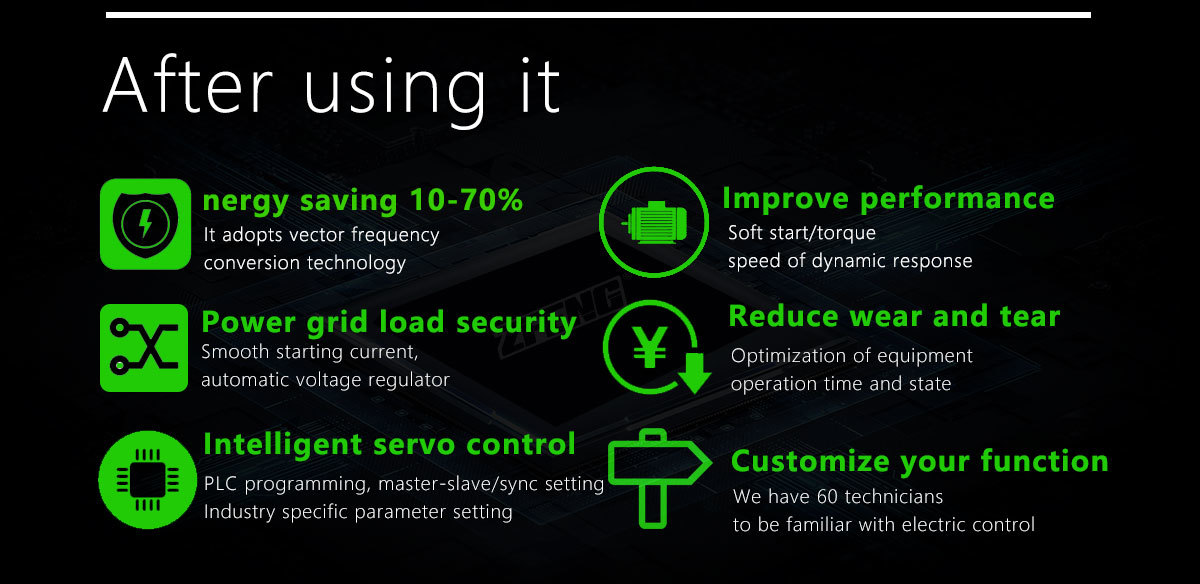

development and production and sale of products of “energy saving

and control speed and variable speed” , Zhufeng has been a very

good supplier for energy saving and automation control solutions .

With it’s own brands: “ACI”,“ZFENG”, Zhufeng has developed DLT

series products including vector and universal variable frequency

drive, servo system, energy saving cabinet, industrial power saver,

soft starter etc. Applications including ceramic, machinery,

petrochemical, metal, textile, food, papermaking, cement, water

supply, plastic injection, central air-conditioning, smart

building,etc.